Services

How does a CO2 Laser Work?

In a Co2 laser cutter, light is produced when electricity runs through a gas-filled tube with mirrors at both ends. One mirror is fully reflective while the other one lets some light come through. These mirrors guide the laser beam into the material that is to be cut. The gas is typically a mixture of carbon dioxide, nitrogen, hydrogen, and helium.

Any light produced by Co2 lasers is extremely powerful compared to normal light. This is because of the mirrors that bookend the tube of gases. These mirrors reflect most of the light traveling through the tube and cause the light waves to build in intensity. The light only passes through the partially reflective mirror when it becomes bright enough.

Since the light from a laser is infrared, it is invisible to the human eye. It also has a very long wavelength. It can cut a variety of materials, including cloth, wood, metal, glass, and paper. The intense heat from this light vaporizes the material that is going to be cut, leaving an accurate, smooth finish

Advantages of laser cutting and laser engraving

- Non-Contact Process – The beam doesn’t physically touch the material it is working with; instead, it causes the material to melt through intense heat. This causes minimal damage to the material and the machine.

- Low Power Consumption – Laser cutter machines have low maintenance costs and only need inexpensive replacement parts.

- A Safer Method – Laser cutting is much safer than other forms of cutting since it doesn’t use a blade. The beam itself is sealed in a tight little lightbox.

- Incredible Precision – Lasers produce highly accurate and precise cuttings that have clean cuts and a smooth finish.

- Many Applications – Laser cutting is not just for manufacturing processes – it can also be used in the medical sector, as well as in the arts.

.

Services offered

Wood laser cutting and laser engraving

Wood is a popular choice for laser cutting and laser engraving.

We supply MDF Supawood which can be laser cut as well as laser engraved. We offer it in 1mm, 3mm and 6mm thicknesses.

We can also laser engrave on a variety of other woods such as hardwood and as well as a veneered finish. We can laser engrave on wood items ranging from tool handles to coathnagers which make great gift ideas.

Laser cutting and laser engraving of Textiles

Most textiles can be laser cut. Leather can also be laser engraved. This can be used for making customised gifts such as bags and wallets.

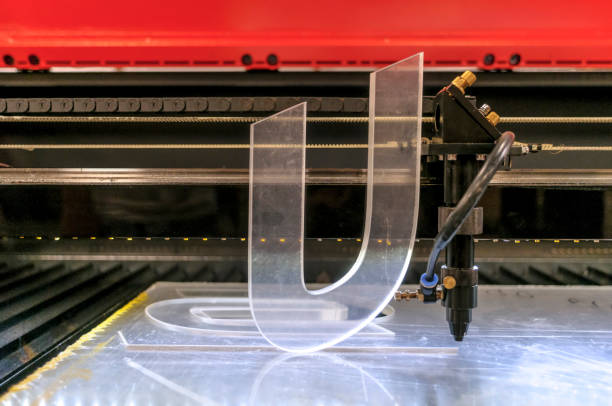

Laser cutting and laser engraving of Acrylic/plastics

We can laser cut and laser engrave a variety of plastics ranging from 0.9mm up to 10mm thicknesses. We supply acrylic in a variety of colours in either 3mm or 5mm thickness and clear acrylic ranging from 0.9mm up to 10mm thick.

We can also supply and laser cut ABS and Polycarbonate.

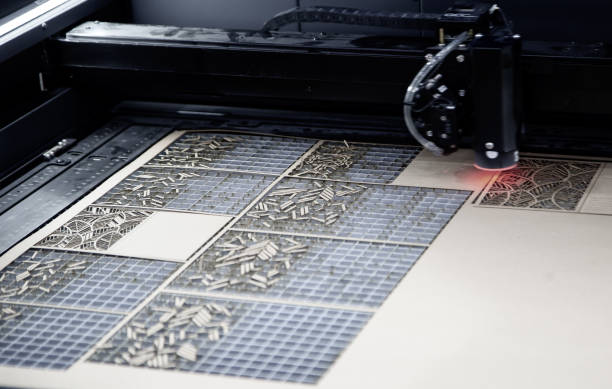

Paper and cardboard laser cutting and laser engraving

From intricate laser cut wedding invitations to party decor items, we will be able to assist no matter how big or small the job may be. All paper needs to be supplied by clients. These can be sourced from craft/stationery shops or specialised paper suppliers. We can also laser cut cardboard which can be used for furniture and architectural models.